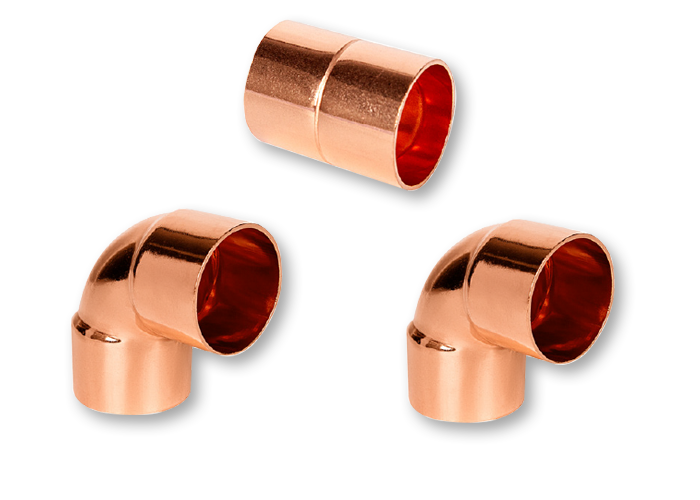

R410A Copper Fitting

Description

Installation

Working Pressure Chart

Description

· Comply with Australian Standard AS1571

· Manufactured in ISO9001 certified facility

· Designed and Manufactured to suit refrigerant R410A

· Engineered and Manufactured to remove stress and fatigue focus points

· Rigorously quality control system to ensure each fitting meet required safe working pressure

· Full series items available including Tees, Elbows, Couplings, etc

Installation

· ICOOL R410A copper fittings can be installed easily by tradespeople in accordance with the methodology recommended in AS HB40

· 15% silver solder is recommended for brazing R410A copper tube or fittings or other high pressure applications

Working Pressure Chart

| Size | OD (mm) | Raw Material Wall Thickness (mm) | Possible Lowest Point of the Fitting(R410A) (mm) | Max Working Pressure at 65°C (bar) |

| 1/4'' | 6.35 | 0.81 | 0.67 | 142 |

| 5/16" | 7.93 | 0.81 | 0.67 | 111 |

| 3/8'' | 9.52 | 0.81 | 0.8 | 110 |

| 1/2'' | 12.7 | 0.81 | 0.8 | 81 |

| 5/8'' | 15.88 | 1.02 | 0.9 | 72 |

| 3/4'' | 19.05 | 1.14 | 1 | 66 |

| 7/8' | 22.23 | 1.4 | 1.15 | 65 |

| 1'' | 25.4 | 1.63 | 1.3 | 65 |

| 1-1/8" | 28.58 | 1.83 | 1.5 | 66 |

| 1-1/4" | 31.75 | 2.03 | 1.65 | 66 |

| 1-3/8'' | 34.93 | 2.03 | 1.83 | 66 |

| 1-1/2" | 38.1 | 2.4 | 2 | 66 |

| 1-5/8'' | 41.58 | 2.41 | 2.3 | 70 |

| 2-1/8" | 53.98 | 3.3 | 2.75 | 64 |

| 2-5/8" | 66.67 | 4.2 | 3.5 | 66 |

| 3-1/8" | 79.37 | 4.92 | 4.1 | 65 |